The year 1900 – Founding of Frank & Co.

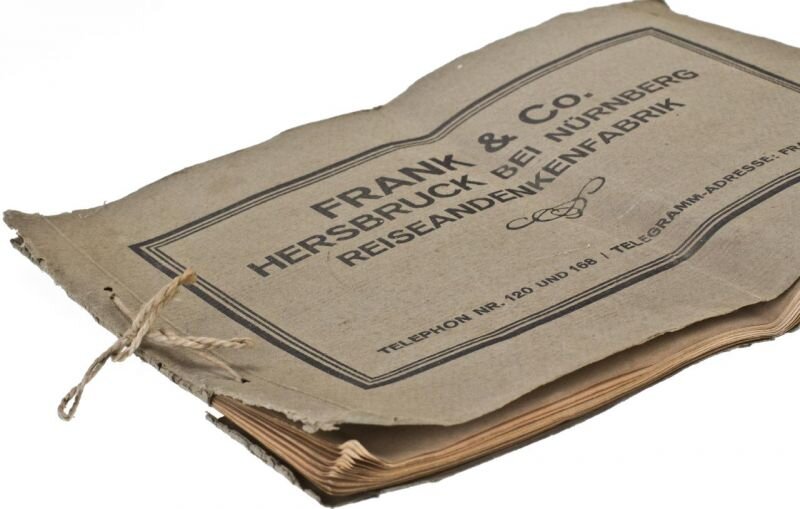

In 1900, Karl Frank founded the company Frank & Co. Reiseandenkenfabrik (Frank & Co. Travel Souvenir Factory) in Nuremberg.

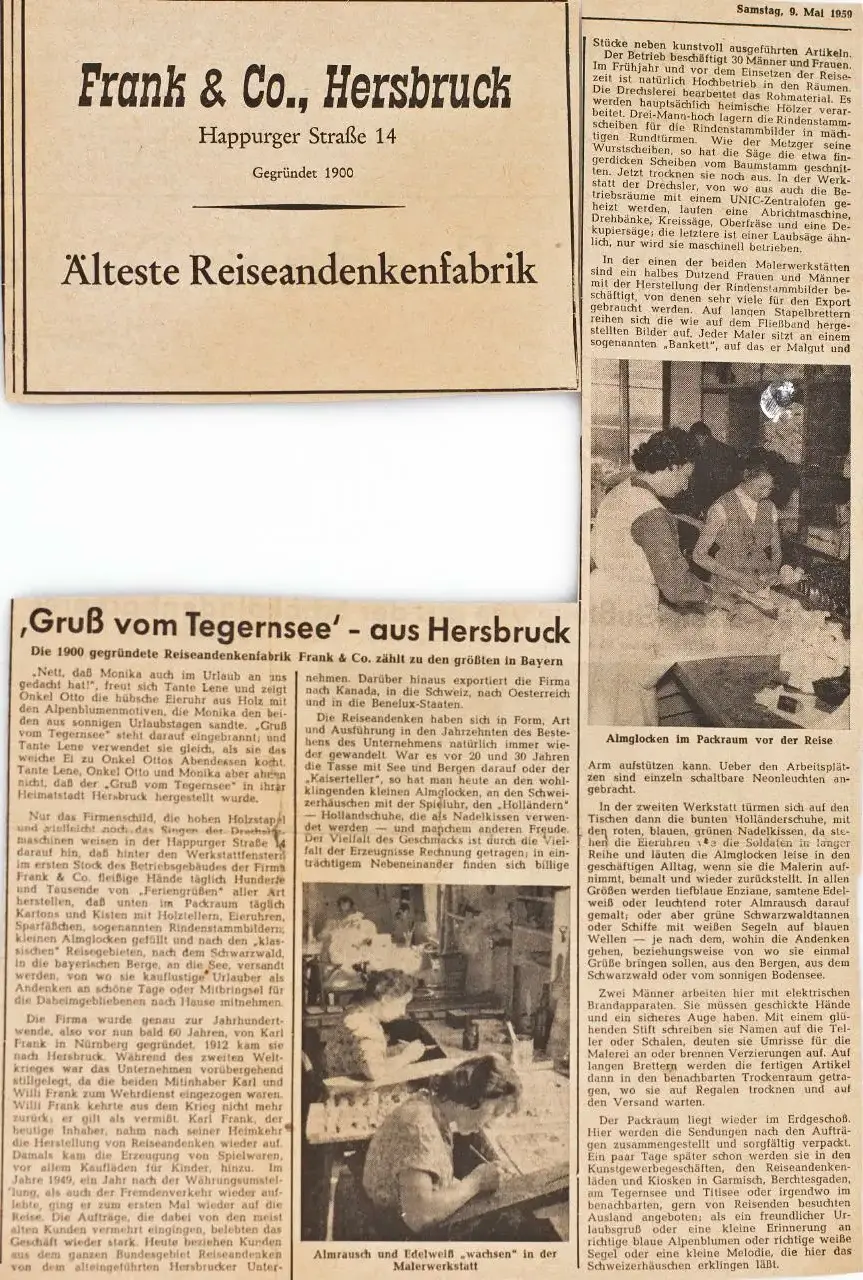

The company Holz Frank, formerly known as “Frank & Co.”, was founded over 120 years ago at the turn of the century in 1900 by Karl Frank in Nuremberg. As early as 1912, the company relocated to Hersbruck. During the Second World War, operations had to be suspended as the owners, Karl and Willi Frank, were conscripted into military service. Sadly, Willi Frank never returned and is still listed as missing to this day.

After the war, Karl Frank resumed the production of travel souvenirs and expanded the range to include children’s toys. With the economic upturn following the currency reform in 1949, the company regained many of its customers. Since 1959, Holz Frank has been exporting successfully to Canada, Switzerland, Austria and the Benelux countries.

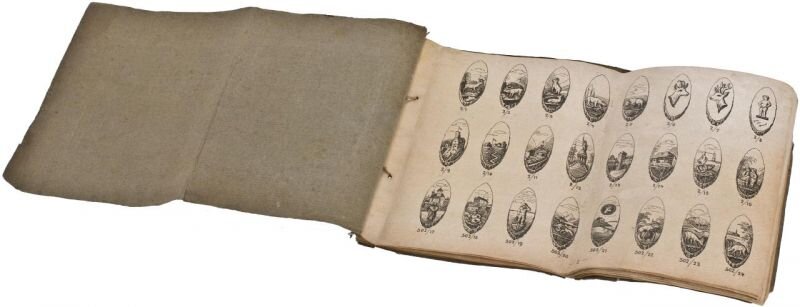

Over the decades, the forms and motifs of travel souvenirs have evolved. In the 1930s and 1940s, these were mainly mugs with landscape motifs or the popular “Kaiser plate”. In the 1960s, new items were added: small bells, Swiss-style chalets with music boxes, pincushions in “Dutch” design and many other charming keepsakes. This created a diverse range, spanning from affordable items to artistically crafted pieces.

The company employed around 30 staff. Particularly before the holiday season, activity was bustling. The in-house turning shop processed mainly local woods into various products. Bark slices for the popular bark pictures were stored in large round towers and then processed using modern machines such as lathes, circular saws and milling machines.

In the two painting workshops, detailed souvenirs were then created. Six women and men produced bark pictures, many of which were destined for export. Each painter worked at their own “bench”, supported by switchable neon lights for precision work. In the second workshop, products such as Dutch clogs, egg timers and alpine bells were decorated with motifs – from gentian and edelweiss to the bright red alpine rose. Depending on the destination, the souvenirs were inscribed with greetings from the mountains, the Black Forest or Lake Constance.

Two employees specialised in pyrography, adorning plates and bowls with names, outlines and fine patterns. Once completed, the items were placed in the drying room before being carefully packed on the ground floor. From there, deliveries were sent to souvenir and handicraft shops in well-known holiday resorts such as Garmisch, Berchtesgaden, Tegernsee or Titisee, as well as abroad. To this day, they remind travellers of the beauty of the Alps, sailing trips on the lakes or the delicate melodies from the music boxes in the Swiss chalets.

<= One of our first field service vehicles, 31 July 1950 – now beautifully restored. Thank you to Austria for the photos and the wonderful care taken of this classic vehicle.

In 1969, Karl Frank handed over the family business Frank & Co. to his sons Werner and Günther Frank. Just one year later, in 1970, Günther Frank withdrew from the company, whereupon Werner Frank took over sole management and changed the company name to “Holz Frank”.

This group photo was taken in 1973 of the team at that time.

Aerial view of the Holz Frank company from 1980

Unfortunately, a chemical reaction in the paint shop in 1984 resulted in the entire company burning down. Production continued in cramped conditions on Happurger Straße in the years that followed.

After two difficult years of construction and continuing to operate in tiny premises, things finally returned to normal in 1986 with the completion of the new building.

Since 2014, Fabian Frank, the third generation of the family, has been at the helm of Holz Frank. Under his leadership, the company has undergone a digital transformation.

The business transitioned to an almost paperless workflow, with catalogues now being created and printed digitally. An online shop was also launched, the product portfolio fundamentally renewed, and investments were made in laser technology.

The introduction of laser technology has enabled us to significantly expand our product portfolio. With this advanced technique, we have introduced numerous innovative products.

In addition, we now offer extended options for personalised wooden promotional items. These can now be customised not only through branding but also with precise laser technology, providing our customers with greater variety and higher quality.

The consistent development of our product range and our specialisation in state-of-the-art laser technology made a significant expansion of our machinery necessary. Today, we operate more than 16 high-precision laser systems. The increasing demand for space led to the decision in 2016 to construct a new company building on the rear section of our premises.

The new building was realised in three construction phases and fully completed in 2020. We are now eagerly preparing to move into our new sustainably designed facility.

The building impresses with excellent insulation, is designed for low supply temperatures and is equipped throughout with underfloor heating. A powerful photovoltaic system with 200 kWp generates more electricity than we need for the entire operation.

A modern high-bay warehouse expands our capacity to over 3,000 pallet spaces with more than 2 million items in stock. The warehouse is fully digitalised, enabling us to provide our customers with up-to-date stock information online at any time. In addition, mobile picking ensures a significantly lower error rate and faster order processing.

In the third construction phase, a new coating system was also installed, offering high capacity and energy-saving heat recovery – another step towards efficiency and sustainability.

Due to continuous growth in recent years, Holz Frank e.K. is now taking a significant step in its corporate development. We are changing our legal form and will now operate under the name Holz Frank GmbH & Co. KG. This change reflects our desire to further strengthen our corporate structures and continue on our growth path.

In 2023, we achieved significant progress in our production technology. Our laser systems were optimised, with some converted to semi-automatic operation. In addition, we expanded our portfolio with the innovative 5C UV printing, opening up new possibilities in design.

At the same time, we supplemented our photovoltaic system with a powerful battery storage unit. This brings us another step closer to our goal of operating entirely CO₂-neutral. Next, we are preparing to convert the entire heating system to an environmentally friendly brine heat pump, scheduled for completion in spring 2026.

By the end of 2025, our entire vehicle fleet will also be converted to electric vehicles – another consistent step towards greater sustainability.

Furthermore, in 2023 we launched our own conservation project to protect native forests.